The Ink Factory

On April 2, 1952 – opening day – the Sun’s Gravure Ink Works were categorized by Hazell-Sun chairman Col. O.V. Viney as ‘the finest Gravure Ink Factory in the country at the present time.’ The factory’s carefully planned laboratory, spacious rooms, and brightly coloured pipe-work were a far cry from the old ink-manufacturing quarters – a cramped area in the middle of the printing plant itself. By the early 1970s the factory was producing over one million gallons (4,000 tons) of ink a year.

The following information on the factory comes from a number of contributors.

* * * *

Ink: Our Lifeline Across the Road

by Dr George Fuchs, Chief Ink Chemist [and ink

factory manager]

[Published in Sunews #33, July 1973]

Our mission in gravure printing – as in all other printing methods – is to put ink on paper under close control.

In gravure we transfer ink not only by the ‘go’ or ‘no-go’ principle (as in letterpress, offset, flexography and screen printing) but also in an infinitely more subtle manner by varying cell depth and ink film thickness.

At Sun Printers we go one step further back by first making the inks for gravure printing. Black ink-making was started by a retired chemist in the early Thirties in the area where the ‘Tiny’ machine is sited at present. The production was expanded to coloured inks at the expense of purchased inks which were completely eliminated after the war.

After the death of the chemist, Mr J. Riley looked after the ink-making department until the appointment of the present manager.

The manager’s first job was to pick a site safely away from the rest of the printing plant, and to design, in co-operation with the then Chief Engineer, a new ink factory. This was done under the stringent building licensing requirements of the period, at a time when the only sensible machine for dispersing pigments in liquid inks was the ball mill. [See this web site’s Timeline, 1952, for an aerial photo of the ink factory under construction. Ed.]

Entrance to the ink factory, late 1950s

Apart from constant changes in raw materials, such as pigments, dyestuffs, resins and solvents, the two major developments since ink manufacture was started at this present site were the introduction of the Kady mill [a high-speed pigment disperser. Ed.] and the supply of the inks to the presses by road tanker and pipeline.

The first development enabled us to extend production without additional building; the second greatly improved security, saved unproductive labour, and simplified the recording of ink movements.

All batches of inks are tested for shade, strength and viscosity as they are made, in order to ensure that the presses are supplied with standard inks whose tolerance is as small as is feasible.

As we are spending about £700,000 per annum on raw materials, their selection and processing is of supreme importance. They are also the subject of a large proportion of the tests and examination in the laboratory.

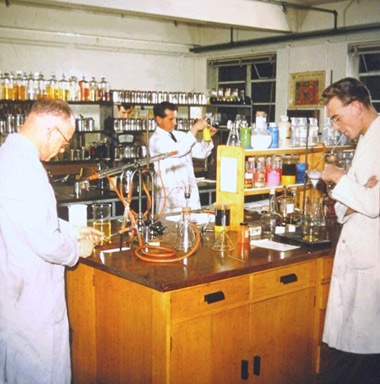

In the ink laboratory. Left to right: Jack Cohen (deputy ink chemist), Ray Taylor (chiefly involved with lab trials), and Ed Joyce (chemist).

Although ink transfer plays a vital part in any printing process, and quantitative research has been carried out, the forces involved are still not completely understood. The effect of ink composition, the physical properties of inks, the shape and surface of cylinders and paper – all these have to be examined piecemeal until, some time in the future, the transfer can be integrated into one formula.

The chemists in the ink department are also engaged in the testing of ink behaviour after transfer, i.e., drying and rub-resistance. It is in these respects that the responsibility of the Ink Factory extends into the Machine room and the Warehouse, and ultimately to the newsagent’s counter.

For that matter, it extends even into the lady customer’s drawing room. for ink, having transferred from the cylinder to the paper, shows such an affinity for plastic coverings that the printed page (though reversed) may transfer once more, under body pressure and at body temperature, as a faithful, indelible, but unwanted image onto her best furniture!

The colorimetric properties of an ink extend the ink technologists’s field of responsibilty into the reproduction areas. The colour of the process inks represents an important parameter for colour separation, scanning and retouching. In the absence of a known method of evaluating process ink colours, Dr L. Planskoy is working at the Imperial College on a research project which is also sponsored by a French E.R.A. member, Imprimerie Chaix-Desfosses-Néogravure.

Meanwhile, the main responsibility of Sun’s Ink Factory is to make sure that no machine ever has to be stopped because the ink tank has run dry. As our storage capacity was designed for a smaller ink consumption, this simply means that we have to fill any void in the storage tanks in Ascot Road between the paper stores and the railway line.

This requires, on average, the transfer of inks in five 1000-gallon road tankers in 24 hours, to which the Machine Room adds nearly the same volume of recovered solvent. All inks are supplied at the same viscosity so that the machine operators can safely estimate the effect of addition to the ink duct.

A crew of 19 operators and one foreman are engaged on three shifts for securing the lifeline. They also cover a large proportion of the ink consumption of Harrison and Sons at High Wycombe.

Sidebar: The Cerutti-Harris Trophy for excellence in printing has been won by Harrison and Sons for the Tutankhamen souvenir edition of the Evening Standard. The 4-colour process inks were supplied by Sun Printers’ ink factory.

* * * *

Woman’s Own

‘transfer’ their affections

[From Sunews #40, June 1974]

“Embroidery has come a long way since traycloths. Now it’s big fashion news – in flowers, scenes or initials. But the cost of embroidered fashion almost matches the national debt! ... For the first time ever Woman’s Own brings you transfer initials and designs to cut out and iron onto fabric.”

Readers of Woman’s Own of 18th May are unlikely to have overlooked this introduction to a colourful 6-page supplement given over entirely to embroidery transfers that could be cut out of the pages and ironed onto clothes and accessories for subsequent embroidery in various colours and stitches.

They might have missed, however, editor Jane Reed’s charming tribute on the contents page to Sun Printers, who print the magazine, and to Dr George Fuchs, who developed the special inks that were used for printing the designs and motifs in the supplement.

Retiring person that he is, Dr Fuchs was somewhat taken aback at this very public acknowledgement of the development. “It was the work of a team!” he protested to Sunews. “Much of the formulation was done by Ed Joyce and young Ian Smillie.” (Ed is operations manager of the ink factory and Ian is a laboratory assistant.)

Dr Fuchs did admit, however, that it was he who produced the transfers idea when Miss Reed, lunching with the directors last autumn, said she was looking for a new feature for her magazine. There was the inevitable teasing when his name appeared in the magazine; and someone actually suggested that if the transfers did not work, half the women in England would be after [Dr Fuchs], brandishing their electric irons.

“In fact,” he said, “I have not had one complaint, so I feel that the transfers must be working well. We certainly tested the inks thoroughly, both in the laboratory and on the press. We held a demonstration for the girls of Woman’s Own, who were invited to try the transfers for themselves. Yes – we even provided the iron!”

Dr Fuchs said that the patterns in Woman’s Own were the first that could be transferred to both natural and man-made fibres. For printing in a magazine the ink also had to be indistinguishable in appearance from the rest of the text and, on the press, just as practical as normal mono black.

This is achieved by a process called sublimation. Instead of literally being transferred from paper to fabric, Sun’s new ink evaporates as a solid fume and condenses again on the material. The old method, Dr Fuchs explained, involved a thick layer of ink which simply would not have lent itself to the printing of mass circulation magazines.

Of course, in the printing of Woman’s Own it is impossible to avoid using the ‘embroidery’ ink on the rest of the cylinder. So, if you knew the imposition, you could also make transfers from other parts of the text and from some of the mono advertisements. Not that anyone would want to do so, in preference to the charming initials and designs in Miss Reed’s supplement.

An interesting and again gratifying tailpiece to this story is that inquiries have already been received at Watford from continental printers who would like to try the same thing. But Sun Printers, and Dr Fuchs and his team, are hanging on to their secret.

* * * *

About the inks

The manufacture of inks for the printing industry is a highly technical, highly specialized business that involves working with a complex set of variables – not just the amount of ink to be produced and the intended purpose of the printed product, but also the size and dispersal of pigment particles, opacity, viscosity, yield per pound, tack, resistance to smudging, resistance to sunlight, and a host of other considerations.

Inks are essentially compounds of pigments (for colour), resins (for adhesion), solvents (for drying), and additives (including deodorants, and wetting agents for improving pigment dispersal). The inks used in the gravure printing process must be free-flowing so as to quickly fill the shallow, recessed cells of the cylinder surface, yet must be formulated to dry with the evaporation of the highly volatile solvents that are part of their make-up. On gravure presses, heat is applied to the printed web after each colour is laid down, in order to hasten evaporation.

Sun’s ink, once manufactured, was moved by tanker from the ink factory to a series of underground storage tanks located adjacent to the railway bridge in Ascot Road, near the entrance to the paper warehouse. The solvent tanks were located there as well. From this store, the materials were pumped to the presses. Only special colours and additives continued to be handled in barrels.

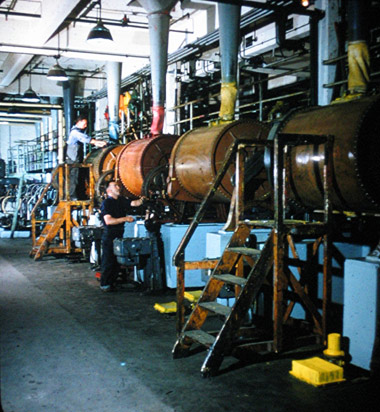

Because of the volatility of the solvents used to make gravure inks, pigments must be processed inside completely enclosed mills. Here in Sun’s ink factory, ink pigments are being ground to a predetermined fineness by ball mills. The mills contain a rotating chamber filled with ceramic balls and are charged from the top with pigment, mediums (varnish), and spirit (solvent).

Multi-coloured ink pipes run along the basement ceiling below the gravure machine room. These pipes carried inks, solvent, medium (a varnish used to lighten or reduce colour strength), water, air, and other services from machine to machine. The plain, unpainted pipe was likely ‘spirit’ – the xylene/toluene mixture used to thin the ink’s viscosity. It was a closed cycle: the volatile vapours were driven from the printed paper and recovered for further use. (Thanks to Barry Humphreys and Brian Reynolds for these details.)

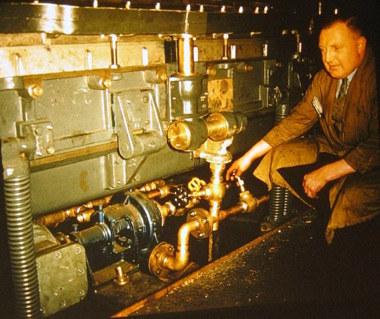

Ink factory foreman Bert Clements crouches between two Goss units, at the back of the duct of one of them. The pipework ran from the ink pump under the unit, up the vertical pipe, to a long horizontal chamber within the duct head, where the entire width of the cylinder could be continuously flooded with ink from the unit reservoir below. The hinge mechanism in the centre of the picture, and also the balance springs, enabled the whole assembly to be swung down and out of the way for cylinder loading. Before performing this manoeuvre, machine operators had to make sure that the ink level was low enough to prevent spillage when the assembly was lowered. Bert has his hand on one of the valves that allowed for ink pump change without draining down. Everything looks uncharacteristically free of ink because the Goss presses, of which this is one unit, had only just been installed (1958). (Thanks to Barry Humphreys for this information.)

This photo, taken in the early 1980s, shows (far right) two of the factory's five road tankers, used to transport the ink from the factory to the ink depot across the road.

From experience...

Barry Humphreys recalls that on the newer presses

“the correct ink colour, spirit, and medium were fed by

pipework direct to each print unit. Any extras had to be added by

hand at the unit. This pipework was a major breakthrough; before

that, there were barrels and cans all around

the place – a tremendous fire hazard (Rembrandt’s

fire was a classic case). Many of the older presses were still

like that when I started.”

He also remembers ink factory personnel.

“All these guys were very helpful to me in getting me good

marks in the H.N.D! I spent some time with them during that

period and they were all mathematicians! In the lab there was, of

course, the deputy, Jack Cohen – an archetypal professor

type. He once said that when he and his wife went out to friends

for dinner he always

took a good book. If nothing sensible had been said in the first

10 minutes, he would start to read!! George Fuchs, who was in

charge of the Ink Factory, gave him a very hard time and would

bawl him out in front of the office or operatives at will. Ray

Taylor was concerned more with lab trials in the Ink Factory. In

the lab picture [above] he looks very young for his age. He must

have had a picture in the loft! He was a great rugby enthusiast

as were many of them over there. Ed Joyce was the chemist who

took over from George Fuchs in the last days of the Ink Factory.

Very bright guy. Some of the other names from that lab: Frank

Thirtle, George Marsden, John Goldbart. The latter now in Israel

on a Kibbutz and very much into rugby still!”

* * * *

At the Sun, having so much solvent evaporating into the air of the vast gravure machine room was not only a health hazard but also (solvent being extremely expensive) a costly loss to the company, involving tens of thousands of pounds annually. The building of a new solvent recovery plant [see Facts & Opinions article – Ed.] at the same time as the ink factory meant that, from then on, the vapourized solvent would be drawn away from the presses by fans, processed into liquid form again, and stored for reuse.

While solvent recovery dramatically reduced the amount of solvent vapour in the air of the machine room, Sun chargehand Len Leach remembers the pervasive smell of the gravure ink, “which was caused by xylol, a solvent added to the ink to obtain a consistency suitable for printing. It smelled throughout the works, and a sandwich taken home from the works would have become inedible. The person whose duty it was to clean out the ink ducts was the most exposed to the fumes, and often suffered breathing problems. This fact made the headlines when a person at Odhams died as a result. When we printed Picture Post, a solvent was used that smelled like violets. I used to be able to tell by the smell whether a magazine had been printed by gravure.”

And machine minder Jack Clarke recalls being able to “smell the Sun works a mile off before the solvent recovery system was put in place. I remember that my father’s attaché case, when opened at home, always stank of fumes from the works. Going between the units and opening the ink ducts, you really felt drunk. Men would take turns spending time outside, not just to get away from the the noise, which left your ears ringing after half an hour and prevented any kind of conversation near the presses, but also for relief from the fumes. At lunch the men might walk around Cassiobury Park for some fresh air.” They used the term ‘going on blow’ for taking a break from the machine room. It pretty well meant getting outside and getting a blast of fresh air into the lungs.