Gravure Printing and Gravure Presses Explained

by Graham Leech

First, a word about colour printing. The average person has no idea whatever of the complexities of printing – and especially, of colour printing. In the first few hours of life, every baby sees colours on toys, furniture, clothing. And a few months later comes the first coloured book. So people grow up not giving a second thought to colour printing. They don’t have to oil it, pump it, or wind it up, put batteries in it, repair a puncture in it, or replace its fuses. It’s just there, to be looked at.

But colour printing is not what it seems, nor is it simple. To obtain full colour, the three processes (letterpress, lithography, and gravure) all depend upon printing only the primary colours (yellow, red, and blue, plus black), and precisely superimposing them so that all the other colours of the spectrum (orange, green, purple, etc.) seem to appear. Black adds the type, and some crisper ‘modelling’ to the colours. The final apparent printed colour is therefore a tone made up of one or more primary colours, where the tone ranges from the palest (highlight) tones to the darkest (shadow) tones.

Now, let’s take a closer look at the gravure process, beginning with the mechanics and scale of the pressroom.

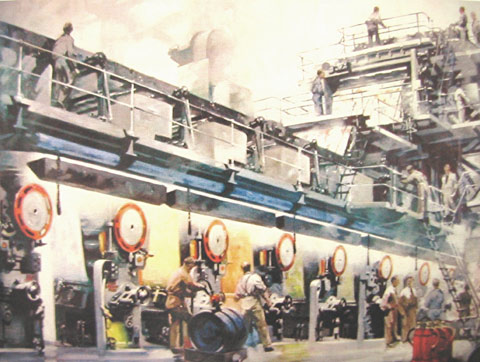

This image serves as a good example of a large gravure press: it is part of artist Leslie Carr's rendering of an 18-unit Goss press. You can see eight printing units with their orange hand-wheels for setting impression, the last almost hidden by a ladder. For the purposes of this explanation, we’ll number the printing units, starting at the left side of the picture, from (1) to (8).

In the picture, a web of paper is seen coming up through the floor from the reel-stand in the basement, between units (1) and (2): it goes up to tension-control rollers and then left (but invisible here) into unit (1) for printing in black on one side only, then drying before reversing back towards the other units.

You can see the unprinted (white) side of the paper going into the yellow unit (2) (there’s a yellow ink spill near the floor). After impression and drying, the paper goes down (with the yellow visible in the picture) into the red unit (3), which adds the red colours and the orange tints through combination with the yellow. This action repeats into the blue unit (4) to add blue, plus creating green and purple through combination. Then, lastly, into the black unit (5), which adds the black text and also gives modelling to the colours. Black is also used in very dark colours, reducing the amount of actual colour required, as a minor cost saving and as an aid to ink-drying.

With that web printed entirely (black on one side, four colours on the other), it is then directed to the upper levels of the folder, passing high over the top of units (6) to (8). These three units are printing another web with one side in black and the other side in black plus a second colour (any single colour the publisher selects), before that web also tracks into the folder, at a lower level.

To keep all four colours printing accurately on top of each other (‘in register’) so as to give a full-colour effect, rollers between each printing unit increase or reduce the paper distance between them. This movement is controlled by electronic equipment (‘magic eyes’), which measure the relative position of the colours to each other, and adjust these rollers accordingly.

In the above example, the first ‘eye’ would be after the red is printed in unit (3): it checks whether yellow and red are printing together exactly. If not, a roller above and between units (2) and (3) is adjusted to change the paper distance between these two units so that the colours will superimpose exactly in the web direction: similarly, ‘eyes’ after units (4) and (5) each control the register of the print of the blue and black units respectively.

Colour register across the web is controlled by laterally adjusting the cylinders from side to side, but register across the web does not require as much potential correction as it does along the web.

All these adjustments, along and across the web, are very small (fractions of a millimeter), but happen almost continuously.

In gravure, as just discussed, a cylinder unit prints one colour on one side of the web, which is then dried in a hot oven before reaching the next unit. In contrast, web-offset units print one colour on each side of the paper without drying between units, and all the ink is dried in one oven after the last printing unit.

The gravure printing inks are usually based on petroleum solvent, and are very liquid. At Sun, the inks were piped to each press, and solvent for ink dilution was also piped. Special inks (with stronger or different pigments) and/or other solvents were added from 44-gallon drums when needed for superior colour-matching. One such drum can be seen in the picture, sitting on its bogey.

Sun’s letterpress staff referred to gravure printing, rather unkindly, as ‘wind, piss and pressure’. The ‘wind’ referred to the drying ovens at each unit, where the fumes from the drying ink were exhausted to a system which reclaimed the solvent.

The inks were highly flammable, and fire was an ever-present danger that could even be triggered by static in the paper. The presses had their own fixed, piped, fire-extinguishing systems, and a few portable extinguishers can be seen at the bottom right in the picture. There would also be portable extinguishers on the catwalks above the printing units.

Even after printing and drying, gravure ink could be inadvertently transferred to plastics through pressure. Publishers got the occasional complaint about a reader’s expensive new leather hand-bag having become stained, and had to explain, as nicely as possible, that the ‘leather’ was in reality plastic.

Now, let’s look a little more closely at the gravure press.

The eight units visible in the illustration are only part of one of the two 18-unit Goss presses installed in the late 1950s at Sun Printers. A 13-unit Goss was also installed in 1966.

Each 18-unit Goss was about 140-feet long. Using the men as a yardstick, the folder would have been about forty feet high.

On the far side of the folder (on the right of the picture) the press had another two webs, both of which were printed in four colours backed by black, supplied from a further two reel-stands in the basement.

It’s interesting to note that the 1950s press could print only a little more than a third of its pages in colour, whereas the 1966 press could print three-quarters of its pages in colour (i.e., double the proportion). Most gravure presses have since been designed to print entirely four-colour work. This supports the argument, also demonstrated in newspapers, that advertisers wanted more colour during the last decades of the twentieth century.

Returning to the 18-unit Goss presses: Each had four reel-stands in the basement underneath, with the paper fed through slots in the floor. Full-size reels were about 70" wide with a diameter of 36", and weighed about a ton. Each reel-stand (or ‘spider’) had three rotating arms, each holding a reel of paper – one running into the press, one prepared, pre-glued, and ready to run, and the third the expired reel core to be removed and replaced by a fresh reel. The reel changeover (a ‘flying splice’) was done at full press speed, with the new reel brought up to the same speed as the expiring one: the reel-stand then rotated slowly until the glue on the new reel made contact with the expiring paper, which was then severed with a knife assembly. The operation was impressive to watch (whether successful or not). Such reel-stands are not unique to gravure, being used on newspaper and web-offset presses, too.

Paper is a very expensive component of total magazine production cost, and wastage had to be policed vigorously. The paper mills (mostly located in Finland) had very tight controls to ensure that paper was reeled and packed within precise specifications of tension, strength, and humidity. A substandard reel could cause major problems on the press: it might run so badly that a replacement reel had to be substituted immediately. Because the paper was mostly imported, Sun had to have massive reel storage areas, for different specifications (including opacity and whiteness) and different widths of paper.

Both of the 18-unit Goss presses produced a fixed-size product (Woman’s Own magazine), about 13¼" x 10½" stitched, but untrimmed. The maximum number of pages was 80 in a ‘2-set’ production mode (two copies for each revolution of the press); higher page counts (88, 96, 104, etc.) could be produced in ‘collect’ mode (only one copy for each press revolution). The 18 units printed three webs (each four colour on one side plus black on the other) plus another web of two colours backed by black. So an 80-page issue consisted of 30 colour pages, ten 2-colour pages, and forty black-only pages.

The number of pages in a magazine is largely dependent on the quantity of advertising pages sold for the issue, and this is a seasonal cycle. In slack times, issues would be much smaller than 80 pages, and produced by using fewer reels of paper and/or narrower web widths. Peak advertising season issues (and issues for special events such as the Coronation in 1953) would be much larger – 112 pages or more – requiring the press to run in ‘collect’ mode, with one copy produced per press revolution rather than two copies from ‘2-set’ production, but running fewer and/or narrower reels.

After printing, the webs of paper went into the ‘folder’ (the tower on the right of the picture), where each web was slit into five ribbons: the twenty ribbons were then arranged and collated by the press in the order required for that issue. The (moving) wad of ribbons was then cut at two-page-width intervals (for example, the front and back covers together) folded in half and stitched as a complete magazine and delivered on to a conveyor. The pressmen would occasionally remove a copy for inspection (checking colour, fold accuracy, cleanliness, etc.), and would make adjustments as required. The conveyor ran at a much slower speed, so the magazines overlapped each other: they were then counter-stacked automatically into bundles for 3-knife trimming (i.e.,trimming on the three sides), and then for tying or wrapping for the delivery trucks.

The press crews on this type of press were large, and included the ‘spider-hands’ who manipulated the reels in the basement, and the trimming and stacking team.

Although the press was automated as much as possible, the press crew had to continually monitor the register of the four colours (ensuring that each printed exactly on top of the other), check that the ink was drying properly, and ensure that there was no wear on the cylinders. The printing surface of the cylinders was of copper, plated with chromium, which could wear badly with the pressure of the doctor blade and with impression pressure. Moreover, dirt under the doctor blade could allow ink to escape, or could scratch the cylinder surface, either problem causing the paper to become badly streaked with the colour in that unit. When such faults were noticed at an early stage, they could be repaired quite easily; otherwise, a replacement cylinder might have to be made, which could take several hours and jeopardise the delivery schedule.

The paper was mildly elastic, and tension throughout the press had to be evenly maintained so that the four printing colours superimposed properly; moreover, the paper could shrink, owing to the heat in the ovens that dried the ink. An electronic system (the ‘Autotron’) monitored the register in the web direction by checking the position of special printed marks: quite an achievement, as the webs were running at speeds up to about 1,500 feet per minute.

If anything went wrong the whole system had to stop. For example, if a flying splice failed, the press had to be stopped and then put on crawl speed until the new web had been threaded through the printing units and folder. Some of the printing units would also need to be cleaned.

Those two Gosses were unusual in that they had two folders, so that if one got hopelessly jammed with paper the other could be threaded up and run instead, while the jammed one was disconnected from the drive and remedied. The folders were so tall that, at the press design stage, serious consideration was given to equipping them with personnel lifts. If one magazine issue had a major change in colour placement from the previous issue, there would be several crew threading the ribbons through the folder – which could also happen as the result of a multiple web-break. (Many other presses had two folders, but for the different reason that the whole press could be run into one folder, or two halves could run independently into the two different folders.)

One other feature of all the Sun’s gravure presses was that all the folders were ‘ribbon’ folders, rather than ‘former’ folders. Each ribbon was the same width as the untrimmed page-height of the product. With a former folder, the ribbons are twice as wide, and they are arranged together before running over a former to fold the wad to ribbon width: the product of this type of folder has pages closed at the top (the ‘head’) with a fold, whereas the three sides of a ribbon product are all open. Unless a press is all four-colour, a ribbon folder allows a much wider choice of colour fall, but with twice the number of ribbons running into the folder there’s a greater chance of a paper break, and the press takes longer to web up.