The Decade of Expansion, 1950–1960

by Pat Valentine

Compiled from: issues of Sun News (including Rembrandt), issues of Impressions, and the Sun archives, with additional input from Barry Humphreys

When Sun management announced, in late 1953 (the exact date is unknown), that the firm was about to embark on a major expansion, the planning of ‘Operation Sunrise’ was already well along. A new paper store had been built in 1950 and a state-of-the-art ink factory had been opened in April 1952, and now it was the turn of the rest of the works to be brought up to date. The plans involved the constructing of several buildings, the enlarging of others, the raising of roofs, the shifting of tons of earth, machinery, and materials, the addition of improved (and newly designed) equipment – in effect, a total reorganization and modernization of the factory.

This ambitious project had barely been launched when a further expansion project was announced – a large factory extension on recently purchased land south of the railway line. A state-of-the-art solvent recovery plant was also to be built, an ink depot to be added, the Paper Store to be expanded. Basements would be modified and used for new purposes. A second tunnel would be run under the railway line to link Sun facilities. Prototypes of all kinds, from the technical (a new drive to rotate cylinders) to the mundane (employees’ lockers), would be tested, advanced equipment and machinery would be introduced into department after department, and numerous production lines would be streamlined. Hardly any aspect of the firm would be left untouched, and virtually every department would be moved at least once.

This article and its photos attempt to recapture something of the heady days of that decade, when the sky was still the limit for the Sun.

A New Paper Store

June 1950

The Sun builds a large and modern Paper Store for both flat sheets and reels. Until now, paper has had to be stored in the basement of the main factory. A tunnel is run beneath the railway tracks to link the Store with the rest of the works.

The new Paper Store, photographed in 1951, fronting on Ascot Road. The passageway that leads under the tracks can be seen on the left. (Photo supplied by Basil Boden)

A New Ink Factory

April 1952

The Sun builds a modern Ink Factory, complete with laboratory, to produce its own gravure ink.

The Ink Factory on Ascot Road, opposite the Paper Store. (From the archives)

‘Operation Sunrise’

1953

Plans for a major factory expansion are announced to employees. The intent: to replace an old factory with a new one; to make Sun Printers ‘The Leading Printing House in the World.’

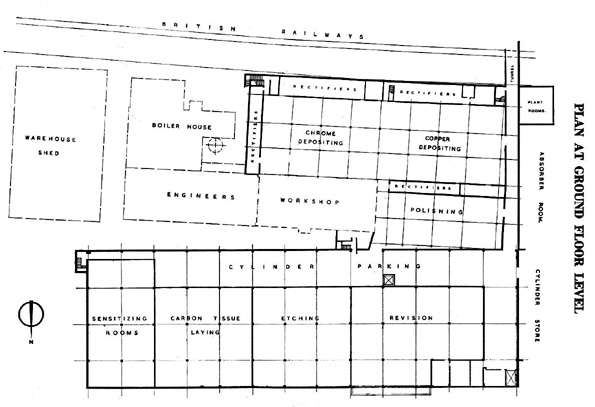

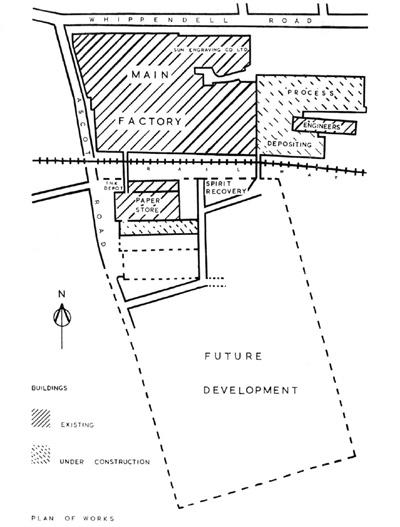

Plan of the East Extension. The new buildings will run parallel with Whippendell Road and the railway line. Chrome Deposition, Copper Deposition, and Polishing departments will be together in a single-storey building near the railway. Sensitizing, Carbon Tissue Laying, Etching, and Revision departments will share a large multi-storey building closer to the road. (From the booklet ‘Operation Sunrise’)

October 1954

East End Extension – Excavation is proceeding as quickly as the weather permits.

Gravure Machine Room – Alterations to the roof and basement are under way, although slowed by poor weather conditions.

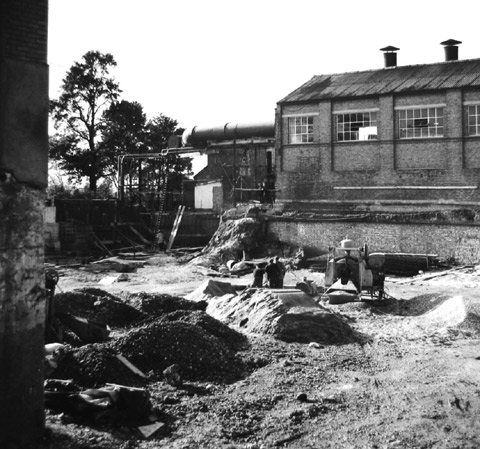

Land near the railway tracks is shored up as a first priority in the excavation for the single-storey building. (All six photos by Leslie Hodge)

Excavation for the single-storey building, with the first spirit recovery plant, built in 1939, in the background.

The single-storey building will be flanked on its other three sides by the Engineering Shop (on the left), the boiler house (centre), and the tracks (to the right).

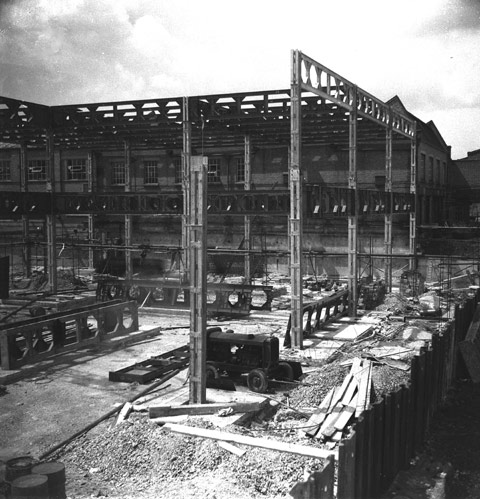

The foundations are now laid and the structural steelwork is going up.

The construction site as seen from the boiler house, looking towards the spirit recovery plant.

Excavation is also proceeding for the multi-storey building whenever the frequent rains allow.

December 1954

East End Extension – Despite the unfavourable weather, excavation is progressing satisfactorily. Management, the Operations Research Department, the architect, and the technical specialists dealing with lighting, air-conditioning, and other services have completed the detailed planning of the basement of the new buildings.

Gravure Machine Room – The new roof of the first bay has been completed and the bay recommissioned. Work is proceeding well on the second bay.

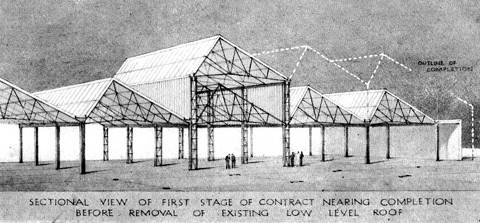

Architect’s drawing showing how the new roof will be built above the existing roof in each bay of the Gravure Machine Room. Each old roof will be dismantled only after the new one has been completed. (From the booklet ‘Operation Sunrise’)

February 1955

East End Extension – The extension is on schedule, the bulk digging is 75 per cent done, the foundation of the single-storey building is nearing completion, and the structural steel work is half erected. The building contractors will next construct shuttering for the casting of the concrete slab roof, after which the north light portion of the roof will be glazed and sheeted. Construction is also proceeding on the multi-storey building (which will be called the Process block).

Gravure Machine Room – Despite relentlessly bad weather conditions, steady progress is being made on the second bay. The steel stanchions have been erected on the third bay.

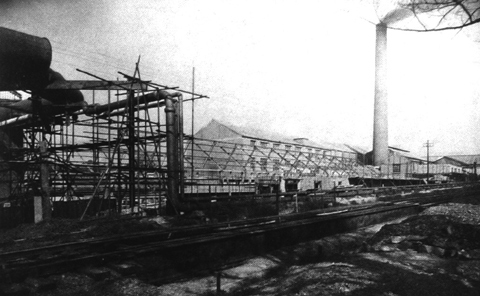

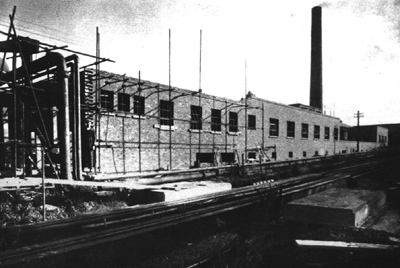

The single-story building takes shape alongside the Engineering Shop. (Photo by Frank Symmons, Rembrandt Studio)

April 1955

Gravure Machine Room – Work on the second bay is proceeding smoothly. By mid-April the bay will be recommissioned. Work on the third section is gathering momentum and is on schedule. This major alteration to the premises will be completed a month or two before the arrival of the new big presses.

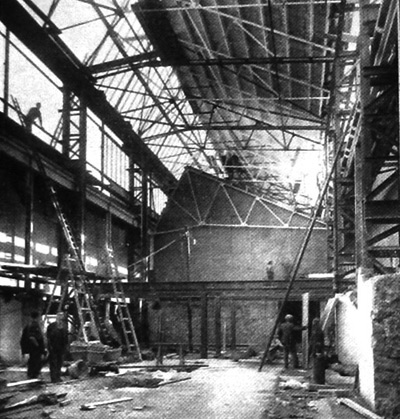

The floor of the Gravure Machine Room is demolished, to be replaced by one strong enough to support the new presses. (Photos by Frank Symmons)

Machine components pile up as the huge rotary presses are dismantled prior to their move.

June 1955

East End Extension – A contract has been awarded for electrical and mechanical services for the single-storey building. Work on the department layouts is well advanced. Preliminary plans have been submitted to individual departments for review and suggestions. Experiments are being carried out to determine the best type of lighting for each department.

Paper Stores – A new White Paper Store is being created to provide storage space for flat stock that is currently kept in the reel stores (the South Paper Store) and in the basement. The South Paper Store is being extended to accommodate greater quantities of reel paper.

September 1955

East End Extension – Progress on the single-storey building has been rapid over the last month. Much of the roof is on and much of the service installation work in the under-floor ducts is completed. The steelwork of the Process block is almost all in place and a start has been made on the roof with the hope of completing it before the bad weather starts. Behind the scenes, many complicated problems are keeping the ventilation and lighting experts busy.

Gravure Machine Room – The third bay of the roof is virtually completed. The painters are applying the final touches.

White Paper Store – A new Dexion rack has been erected along one wall. The material used is similar to Meccano, but angled for strength. The rack is 120 ft. by 4 ft. and capable of holding approximately 90 tons, thus clearing floors of thirty large platform loads of paper.

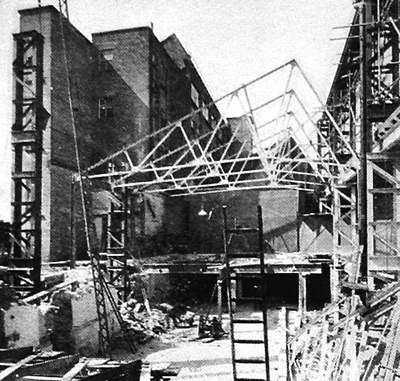

The cylinder treatment rooms begin to take shape in the single-storey building. (Photos by Leslie Hodge)

The structural steelwork goes up for the Process block.

A dramatic shot of the construction site.

November 1955

Gravure Machine Room – The Machine Room is ready for the first of the Goss presses (due in December).

South Paper Store – The first extension, 60 ft. longer than the existing bays, is nearing completion and will add 11,000 sq. ft. for reel storage.

Solvent Recovery – The land at the back of the original Paper Store bays has been levelled. Some of this ground will be used for a new Solvent Recovery Plant.

April 1956

East End Extension – The single-storey building is nearly ready. Some copper and chromium deposition vats have arrived. After the long spell of bad weather, which halted concrete pouring for four weeks, work on the Process block is now proceeding apace. Plans have been produced for the air-conditioning system – one of the largest installations of its kind controlled to such fine limits and, as far as is known, bigger than anything so far attempted in the photogravure field. A new lighting system tailored to the needs of each department has been designed for the Process block. Prototypes of some components of the cylinder-handling equipment are being manufactured and are about to be tested in the works.

Gravure Machine Room – All units of the first Goss press are now in position, the folders are going up, and the Witton James reelstands are being installed in the basement.

South Paper Store – The extension is now in use.

The single-story building nears completion. (Photos by Frank Symmons, unless otherwise indicated)

A Goss press under construction (from a stereo image in the archives)

Early work on the final bay of the Gravure Machine Room.

The completed bay; note the height of the new roof as compared with the old. Printed magazines temporarily fill the space where the presses will soon be reassembled.

To connect development on the south side of the tracks with the main buildings on the north side, excavation is begun on a second tunnel.

June 1956

East End Extension – Construction is progressing steadily but will be completed later than hoped. The single-story building is in final stages but much installation work remains to be done. A number of deposition tanks are being installed, together with the ancillary electrical gear. The ventilating system for the Process block has been redesigned to avoid complications with the ducting systems. Equipment for the Process block is at the design stage: a prototype cylinder stand and trolley are being tested. A reconstructed Tissue Laying machine, to enable ranges of cylinder sizes to be laid on one machine, is ready for testing. A new precision Tissue Laying machine for 77-in. cylinders is due from America in a few weeks’ time. After testing, a new type of bearing is being produced for any Process equipment that requires the cylinder to be rotated. Six hand-made lockers are undergoing trials. They are designed to be connected to the air extraction plant in the new building; the forced-air flow will help clothes to dry.

West End – On the basement level, facing Ascot Road, a new Folding Room is being created. Virtually every machine will be new.

Ink Depot – Along Ascot Road a number of large black tanks, which have been getting in the way of paper lorries for several weeks, are about to be buried between the Paper Store and the railway line and will eventually hold ink and media. At present, the Ink Factory pours ink and media into barrels and cans that are weighed, loaded, carried across the road by lorry, unloaded, and conveyed to the duct tanks. Ink and media will now be pumped through pipes from the Ink Factory to the underground Ink Depot and from there to the gravure presses.

October 1956

East End Extension – The power supply to the single-storey building has been connected. Grinding and polishing machines are being moved in.

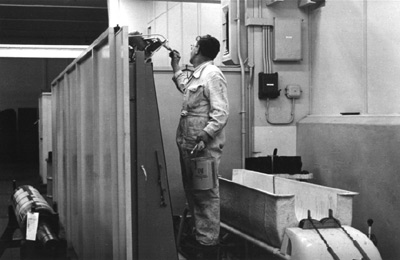

Installation of the grinding, buffing, and polishing equipment. The lathes, honers, and polishing machines will be painted in ‘pleasant shades, with danger points picked out in safety-code colours.’ Handling of cylinders by overhead travelling crane will keep gangways free. (Photos by Leslie Hodge)

Installation of electrical wiring in the Chromium Deposition Room.

March 1957

East End Extension – Installation of the first battery of 77-in. and 30-in. deposition vats for copper and chromium is all but completed. Following preliminary tests, the first production cylinders have been plated in the new vats. The moving in of grinding and polishing equipment has been completed and the department is settling down in its new home. A new type of drive for cylinder rotation is being tested and shows promise. A prototype fibreglass resin-bonded darkroom sink has been constructed and installed in the temporary darkroom of the new 112 Camera. The Mono-Positive Darkrooms and part of the Glass Planning Department have been moved to temporary quarters. The Rinco Planning Department has been moved into the area vacated by the Grinding and Polishing Shop. Work will now start on alterations to the roof over the old Rinco area to provide headroom for the new 30-in. K&B press.

Installation of services and equipment in the Cylinder Plating Department, December, 1956. (Photo by Frank Symmons)

August 1957

East End Extension – Most of the equipment installation for Deposition has been completed. The Carbon and Etching departments have been handed over by the builders and a pilot plant will be in operation by late August, enabling testing of the new equipment under production conditions. The Revisions Room will be ready by mid-September. The first floor, comprising Glass Planning, Colour Retouching, and Studio, will be ready for occupation towards the end of the year.

Gravure Machine Room – The second Goss is under construction. The bed plates are laid and the units are being positioned. Generally, the moving of machines and installation of new plant are on schedule.

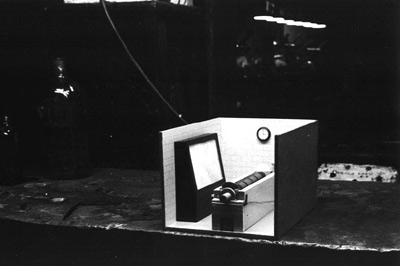

Nothing in this project has been left to chance. Here is a scale model of a new etching booth, with all components in place. (Photos by Leslie Hodge)

A painter adds finishing touches to an etching booth; new colour schemes are being introduced throughout the factory.

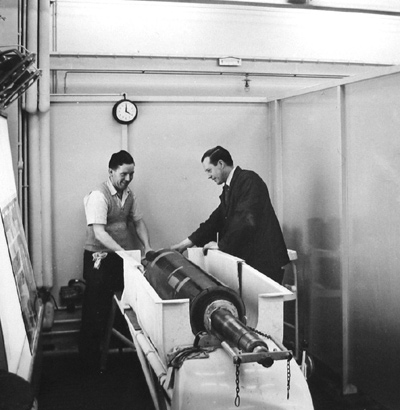

Bert Jeffrey (right) and an unidentified employee test prototype equipment in one of the ten etching booths. Many new features have been incorporated: the telescopic plastic etching trough will accept several sizes of cylinder; a remotely controlled motor turns the cylinders; the large viewing frame can take a full complement of planned positives; a double-deck movable stand holds jugs of etchant; and individual booths can be thoroughly washed down as often as necessary.

April 1958

East End Extension – The Mono Revision Department has moved into the Process block. The Glass Planning Department has moved in on the first floor, the first department to occupy this level. Large quantities of glass were moved in over a week-end ‘with much toil and only one breakage – and that glass, we are informed, was already cracked.’ The new cameras will be moved into the new Studio over a period of several weeks. The new Multichrom and Colour Vertical Cameras have been installed. The Colour Retouching Department is expected to move shortly after the Studio is fully installed.

Gravure Machine Room – The reconstruction and machine-removal programme is making steady progress. The second Goss will be up and running by the end of May. When the work is completed there will be four big presses in line under the new raised roof. There will also be two groups of K&Bs: one comprising 7 mains and 8 Babies, and the other 5 mains and 8 Babies. New Colt ventilators have been fitted in various parts of the Machine Room to improve ventilation.

Letterpress – A new building has been erected alongside the South Paper Store to accommodate finished work.

Ink – New plant has been installed to enable ink and solvent to be mixed in the Ink Factory. The large storage tanks of the Ink Depot are ready to pump ink and media directly to the Goss presses.

Installation of the racks for planned glass positives in the multi-storey building. (Photo by Leslie Hodge)

August 1958

East End Extension – The last negative-planning tables have been installed in the Glass Planning Room, completing the fitting out of this department. The Studio will be settled in by mid-September. All colour cameras are now in the new Studio, except for the Duplex, which will be moved when the Colour Retouchers move. Work on the Mono Darkrooms is completed. New Colour Retouching frames are being installed. Tests of the new plate-drying cupboard for the Studio and Retouching Departments have been satisfactory and the remaining cupboards have been ordered. Drying cupboards for paper negatives and film positives are also being tested. Once the Studio has moved out of the old building, work will begin almost immediately on preparing the Proofing Department for its move to the south side of the cylinder square. As soon as the old copper deposition vats are released, the site will be cleared to house rubber-roller grinding and doctor grinding.

Gravure Machine Room – The MAN #17 press has been scrapped. The second Goss is in production. All ink colours are now being piped directly to the Gosses.

February 1959

East End Extension – The Colour Retouchers moved to their new space at the beginning of November, completing the occupation of the multi-storey building. Preparations for moving the Proofing Department are well in hand. The vacated space will be taken over by Rinco Planning and Mono Retouching.

Gravure Machine Department– The final stages of the reorganization of this department have been embarked on. To facilitate the building operations, certain machines have been scrapped or otherwise taken out of commission.

Main Stores – The Stores are being moved from their temporary huts, opposite the entrance to the East Extension, to the area vacated by the Glass Planning and Rinco Planning departments.

Carbon Printing and Etching departments settle in, December 1958. Overhead cranes eliminate cylinder trolleys from this part of the process. Cylinders will move down the room from the laying machine through the various stages until they are etched, washed off, and put onto trolleys at the end. (From the archives)

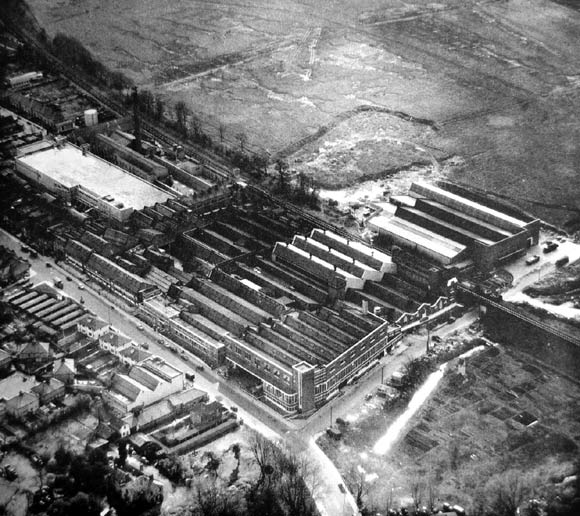

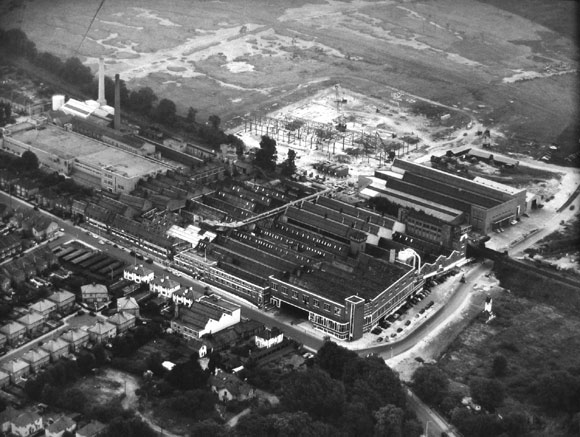

An aerial shot of the Sun works, as ‘Operation Sunrise’ draws to a close. White roofs identify most of the new construction. (From the archives)

December 1959

‘Operation Sunrise’ is by now a virtual fait accompli, with the planned Solvent Recovery Plant the one major piece still to be finished. Ambitious as it was, the project has become just a phase in a broader plan of expansion and modernization.

A New Solvent Recovery Plant / A New South Extension

1953–1959

During these years new projects overlap and build on ‘Operation Sunrise.’ The company acquires 12-1/2 acres of land on the south side of the railway line shortly after ‘Operation Sunrise’ is launched. The land’s future use is already mapped out by November 1955. By then, the new Solvent Recovery Plant behind the Paper Store is in early stages of construction, and further excavation has been started under the railway tracks for the trunking. The November issue of Sun News records: ‘It has been said that a business must grow – or die. Confidence in the future is indicated when a Company embarks on a programme of development and extension such as ours.’

This simplified plan of the factory shows the pre-1953 buildings and those added during ‘Operation Sunrise,’ as well as the location of the newly acquired land.

By October 1956, while ‘Operation Sunrise’ is still roaring ahead at full throttle and the entire factory is more or less on the move, Sun News is reporting preliminary plans for the construction of a large building on the 12-1/2 acres south of the railway. This will be the new home of the Letterpress Machine, Composing, and Foundry departments, some 76,000 sq. ft. of floor space on a single level.

Part of the newly acquired land, already being cleared. In the background, the South Paper Store. (Photo by Frank Symmons)

The March 1957 issue of Sun News reports that the company’s requirements for the South Extension have been turned over to the architects and that a preliminary design for the building is in progress.

In the summer of 1958, orders are placed for plant for the solvent recovery system. An extension is begun to the main boiler house to accommodate the installation of two Danks Economic Boilers (with a plan to eventually have six in all) to meet the factory’s growing needs. The boiler house stack is raised to 120 ft.

In February 1959, Sun News reports that the South Extension building will have 80,000 sq. ft. of floor space. The autumn 1959 edition of Impressions goes further, quoting 83,000 sq. ft., with an additional 5,500 sq. ft. of administrative and editorial accommodation, of which some 1,800 sq. ft. will be in a two-storey building. The Composing Room at Rembrandt will be incorporated into the extension, enabling Sun to again have all its typesetting operations in one place. The general design of the buildings and the disposition of the departments will allow use of the ‘modern flow-line technique.’ Transferring of the three departments to the new building will then allow the Warehouse to be completely reorganized, greater space to be allocated for Despatch, and more floor space to be freed up for the Gravure Printing Department. In addition, it is hoped that various clerical departments can be concentrated in one area. On the north side of Whippendell Road, the building that formerly housed the small Letterpress Machine Department will become the new canteen. The completion date for all this work? The end of 1960.

Aerial view of the works showing (almost in the centre of the picture) the four adsorber chambers of the Solvent Recovery Plant, and behind them, the steelwork being erected for the South Extension. (From the archives)

The skeleton of the South Extension. (Photo by Patrick Ward)

The adsorber chambers. Behind them, the roof of the South Extension begins to receive its cladding. (Photo by Patrick Ward)

December 1959

South Extension – The roof and most of the main structure of the South Extension have been finished on schedule, owing in part to the ‘wonderful summer weather.’ The building is scheduled for completion by May 1960. Careful planning is under way for the move of the departments.

South Paper Store – A further bay is about to be added.

Solvent Recovery – Installation of the plant is well in hand. Metal trunking to carry recovered spirit to the Recovery Plant is being erected over the roof of the factory and will pass under the railway.

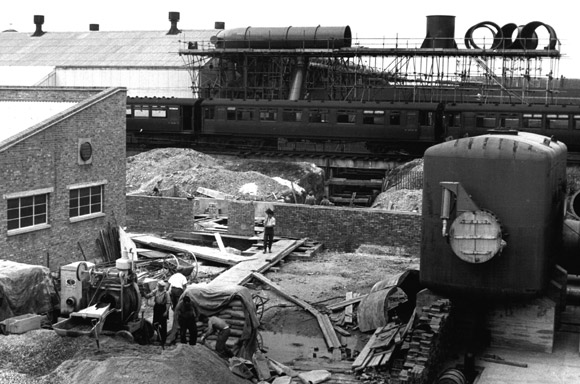

A train passes over the excavation site for the ducting that will link the Gravure Machine Room with the Spirit Recovery Plant. (Photos by Patrick Ward)

The outsized ductwork that will connect the gravure machines to the new Solvent Recovery Plant.

Excavating for the ductwork.

The ductwork snakes across the roof of the main buildings and down under the tracks to the receiving manifold (the horizontal pipe with the oval inspection door at the end) that will feed the adsorber chambers.�

The partly built “conveyor bridge” over the railway tracks. This 320-foot-long installation will link the Process block to the Comps in the South Extension, and will be used to move material, in wooden boxes, between the two buildings.

Looking from the completed Solvent Recovery Plant towards the main factory. The older building with the white window frame may once have housed Gravure Research.

July 1960

East End Extension –All the Proofing Machines have been moved to their new positions, the old Proofing Room is now cleared, and the area is being prepared for the Rinco Planning and Retouching departments. One unit, Pickup & Knowles type, in use since 1912, has been ‘honourably retired.’

South Extension – Between Friday, 29 April, and Sunday, 8 May, the Sun and Rembrandt Composing Rooms are transferred to the new building. Over a thousand pieces of equipment are involved in the move. The Letterpress machines are also moved into their new area at the average rate of two machines per day. Full production is maintained throughout the move. Still to be done in the South Extension: the building of offices, the painting and decorating. All this work is expected to be completed within the month.

Wide-angle view of the interior, giving some sense of the vast work area that is being created. The apex of the roof will be 34 ft. up and the maximum headroom will be 14 ft. (All photos by Patrick Ward)

The north-light windows have been installed and the angle of the south side of the roof trusses has been so designed that the internal cladding (now going up) will reflect back, creating even lighting at working level.

Plenum plant ventilation will ensure that air is filtered and circulated at the average rate of six changes per hour.

The South Extension is ready for occupancy.

Autumn 1960

The autumn issue of Impressions (Vol. 6, No. 1) offers a ‘final pictorial survey’ of the South Extension, showing the new Composing Room, Linotype Room, Monotype Room, Rinco Proofing area, Pre-Make-ready Room, Reading Room, Letterpress Machine Room, Foundry, and Block Store, all in full operation.

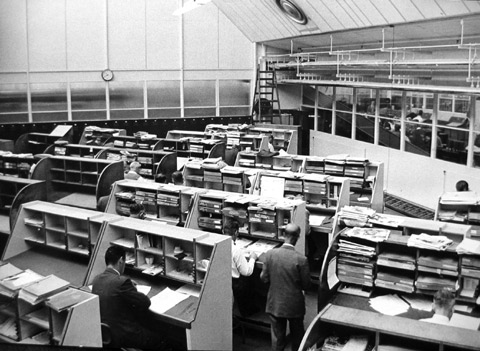

The Readers in their new home. (From the archives)

The new Monotype Keyboard Room. Operator Keith Hobbs is in the foreground. (Photo by Patrick Ward)

Sun Printers, Watford, at the end of a hectic decade.